An inventory management system is a term to describe an inventory control strategy – having a trusted vendor manage the inventory level for regularly used products. Instead of having to continually issue purchase orders or manually place orders, a manufacturer or other consumer of system components, fasteners, and other products would determine the level of inventory they’d like maintained and then turn that responsibility over to a vendor such as Electronic Fasteners, located in Canton, MA.

An inventory management system is a term to describe an inventory control strategy – having a trusted vendor manage the inventory level for regularly used products. Instead of having to continually issue purchase orders or manually place orders, a manufacturer or other consumer of system components, fasteners, and other products would determine the level of inventory they’d like maintained and then turn that responsibility over to a vendor such as Electronic Fasteners, located in Canton, MA.

At Electronic Fasteners, we offer an inventory management system, through which we provide a comprehensive inventory management service. Here’s how the process typically works:

- We set up minimum and maximum product quantities to be maintained for each customer item based on an item usage report.

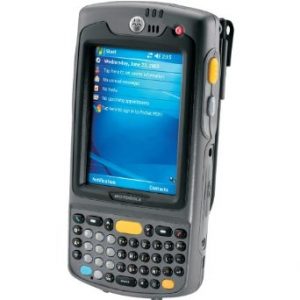

- Each item under inventory management receives a barcode that is entered into our inventory system.

- A team of inventory control specialists from Electronic Fasteners is on the road regularly, checking customer inventories for reorders through our inventory management system.

Our Canton, Massachusetts, inventory management system is highly popular with customers who need to refill inventories on a regular basis. Our service is a cost-efficient, highly effective system that saves customers time and money while enabling their employees to focus on tasks other than checking, ordering, and restocking items. We even provide regular, real-time usage reports to keep customers apprised of current inventory levels, enabling them to anticipate when and how much additional inventory they may need to order to meet seasonal or contract demands, keeping the flow of needed products uninterrupted and avoiding costly production delays.

To learn more about an inventory management system, Canton, MA for your company, contact our experienced inventory specialists, who can schedule a usage analysis.